A device dose is the amount of a medication administered to your client in one dose. Device-dose packaging will be the packaging of an individual dose inside of a non reusable container.

"As a result of its knowledge of the method, Catalent has proven knowledge with filling industrial biologics working with BFS and proceeds to offer added screening on mAbs to supply self confidence that this technology is appropriate for biologics."

Roxtec seals are beautifully built to defend pipes passing through fireplace rated or watertight divisions. They provide huge Advantages in comparison to compounds, sealing plugs and bulkhead unions.

The prefilled injector technology in enhancement by ApiJect is created to be a price-successful drug shipping and delivery procedure to manufacture and become light-weight for decreased transportation expenses. The only-dose format has benefits for security, sterility, and very low waste, which might be In particular significant in minimal-source, establishing regions (4). Although the drug shipping process was made previous to the COVID-19 pandemic, the notion of being able to deliver prefilled syringes on demand from customers was observed as a possible Answer towards the fears about feasible vaccine container shortages from the midst with the pandemic in 2020, plus the US Division of Protection awarded a contract to ApiJect to broaden US manufacturing capability of as much as forty five million doses every month in Biosafety Degree 2 cleanrooms at The Ritedose Corporation in Columbia, SC (five).

The drug, typically contained in the tank, is under favourable force to maintain sterility. A solenoid is employed to deliver a precisely metered dose of the drug product or service on the container.

Micro-taggants are microscopic particles made up of coded details to uniquely establish Every variant by evaluation under a microscope. It might take the method of alphanumeric information depicted on tiny flakes or threads, or fragments of multicolored multilayered laminates with a signature color mixture.

In the main Original move, product is extruded into a mould to form a single-dose container. Up coming, the liquid merchandise is filled and promptly sealed from the atmosphere. All of this is realized in one course of action without having human intervention.

Blow-fill-seal technology has gained Substantially sector focus recently as a result of improved give attention to biologics, proteins and also other intricate alternatives. These significant merchandise often can not withstand publicity to substantial temperatures for extended periods of time without having degradation of their Energetic elements.

It reliably retains your merchandise at the desired temperature and swiftly cools the freshly shaped website plastic containers right before filling them. Therefore, each important fall is secured.

They can be intended to be applied in such a way that they can not be reused or taken check here off without having getting defaced or creating harm to the pack For that reason an overt product could be incorporated inside of a tamper evident aspect for included safety.

Specifically fills porous valve bags with extremely-good powders though that contains dust within the vacuum chamber.

This will also be intended these that some printing is subsurface and stays driving and a few printed matter is on the very best and comes off Using the prime layer.

This aseptic liquid processing technology gives significant rewards over classic filling procedures, as it gets rid of opportunity sources of contamination, for example ingredient washing and operator interventions.

Examine in-depth articles or blog posts by our sealing expert Will Hoffman on why you need to consider changing your latest sealing solutions.

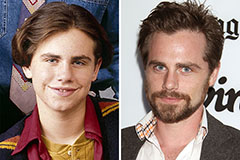

Rider Strong Then & Now!

Rider Strong Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!